Adhesive Peel Tester store|adhesive peel tester : service Work with us to find the right equipment for your ASTM standard ASTM D3330 | Adhesives | Peel Testing Pressure sensitive tape is used in a variety of applications including duct tape, electrical tape, masking tape, packaging, . Resultado da 看丝袜美女图片,就来天天丝袜论坛!. . Check ttsiwa valuation, traffic estimations and owner info. Full analysis about ttsiwa.com.

{plog:ftitle_list}

Resultado da Our DNS Speed Benchmark tool performs an A record lookup for the apex domain name from 200+ locations worldwide. The lookup time is our benchmark for DNS providers' performance in different regions and allows you to debug your self-hosted DNS servers and test routing logic.

Some of the more popular test methods that this device is capable of performing: 1. PSTC: 101 (A, B, C, D, E, F), 4, 15, 55 2. ASTM: D 3330 3. TLMI: L-IA1, L-IA2, L-IA3 4. AFERA: 4001 P11 5. FINAT: FTM 1-6, 10, 11 See moreASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to as the “T-Peel” test because the sample looks like the letter “T” when loaded .The bonded test pieces can also be exposed to potentially detrimental storage conditions such as extremes of heat, cold, artificial sunlight or immersion in product chemicals before testing for peel adhesion. Alternatively, the peel test can be made at high or low temperatures to simulate harsh product environments.

An adhesion tester measures the force required to detach a coating from a substrate. Often called a pull-off adhesion tester or peel tester, an adhesion tester applies a large amount of force to evaluate a coating's bond strength. .

peel testing machine

Work with us to find the right equipment for your ASTM standard ASTM D3330 | Adhesives | Peel Testing Pressure sensitive tape is used in a variety of applications including duct tape, electrical tape, masking tape, packaging, . 180° Peel Test: The most common test, peeling the substrate away from the adhesive at a 180-degree angle. Ideal for evaluating general bond strength. Ideal for evaluating general bond strength. 90° Peel Test: Similar to 180°, but with a 90-degree peel angle. A number of standard test methods are used in the U.S. to measure the peel adhesion or bond strength of pressure-sensitive labels. These include ASTM D 903, ASTM D 3330, ASTM D 6252 and the TLMI 180° Peel Adhesion-Face Stock test method. In addition, as the need to compare test results from other parts of the world increases, it is important to be . A wide range of adhesive properties can be measured by applying tensile or compression forces in a controlled manner. Figure 1. Single- and Twin-Column Materials Testing Machines Figure 2. Test Jig Showing 90. Peel Test on a Pressure-Sensitive Barcode Label Materials testing machines provide a powerful way of evaluating adhesive performance. A .

The Elcometer 1542 is available on its own (Basic Kit) or as a Full Kit which includes a brush, magnifier & ISO or ASTM adhesive tape. There are also Advanced Kits which include all three (1, 2 & 3mm) cross hatch adhesion testers, together with either ISO or ASTM adhesive tape. See 'Technical Information' for a full specification.ASTM D903-98 is a common tensile test used to evaluate the Peel-Stripping Strength of Adhesive Bonds. Back; Home; Products. Materials Testing. Universal Testing Systems. Automated Testing Systems. . To perform a test to ASTM D903, the adhesive materials must be cut into specimens 1" x 12" long. The specimens are then peeled away from either a .

Benefits of Peel/Seal/Bond and Adhesion Strength Tester. The Presto Adhesion Strength Tester serves the purpose of measuring the enduring adhesion or peelability of self-adhesive pressure-sensitive materials. Peel adhesion, in this context, refers to the force needed to remove a pressure-sensitive coated material from a standard test plate under specified conditions, at .The ADMET eXpert 7601 adhesive and peel testing system has been designed to allow users to perform a wide variety of adhesive tests on a single easy to use and compact instrument. You can confidently report results knowing that the system has been engineered to meet all accuracy requirements specified in major standards organizations including .

ADMET’s easy-to-use adhesive peel fixtures are employed by the adhesive industry to test the peel strength, bonding, and shear properties of adhesives. Peel fixtures conform to testing standards such as ASTM D1781, ASTM D3330, ASTM D3167 and can also be customized based on your test application. Below we will explore the types of peel tests .Elcometer 106 Pull-Off Adhesion Tester; Designed to measure coatings adhesion on concrete. Elcometer 106/6 Coatings on Concrete Adhesion Tester; A versatile push off gauge used to test adhesion on flat or curved surfaces. Elcometer 108 Hydraulic Adhesion Testers; Used for an instant adhesion assessment, ideal for thin, thick or tough coatings .

Peel testing of adhesive and pressure sensitive tapes is used for quality assurance, and provides a means of assessing uniformity of the adhesion of a given type of tape. The assessment may be within a roll of tape, between rolls, or between production lots. Adhesive properties for tapes are measured using a standard test surface, a specified angle and test . To ensure quality, manufacturers of products like tape, labels, and wallpaper rely on adhesion testing. Without proper bonding between materials, it is possible for products to peel away or fail prematurely, which could compromise the manufacturer’s reputation as well as market share.. John Bogart, managing director of Kett US, explained, “To create products that require . The store will not work correctly when cookies are disabled. . D3330_D3330M-04R18|en-US Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape Standard D3330/D3330M Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape> new BOS Vol. 15.10 Committee D10

The goal of a peel adhesion test is to determine the adhesive strength level of the material between two materials and is measured in ounces per one inch of tape. The results of this test are surface dependent and are influenced by the testing angle which is typically 90 or 180 degrees. . These cookies do not store any personal information .

To determine T-peel strength, the ISO 11339 test standard can be applied for product optimization. Testing and Simulation of T-Peel Strength . Knowing the force required to progressively separate two bonded, flexible adherends gives engineers an understanding of the direct measure of the adhesive bond strength in a bonded joint.Testing Equipment for Peel Adhesion. A multi-functional peel tester is used to evaluate the peel force in different peel angles, rates, and temperatures (Figure 1). The peel tester is capable of evaluating independent parameters of peel rate from 15-300 cm/min, angle from 0° to 180°, and temperature (by a At measurements of high peel rates, such as those commonly employed using the 180°-peel test, the viscoelastic effects dominate, while at low peel rates, the viscous portion is minimized, which reveals the interfacial strength. The accuracy of the ADT’s displacement transducers enables the measurement of crack speed to be as low as 10-9 m/s.

Adhesive Testing Equipment . A wide array of adhesives is used as a bonding agent for composites. Therefore, they need to be tested adhesion before a product can be used. . ISO 8510 -- Adhesives -- Peel test for aflexible-bonded-to-rigid test specimen assembly ;Product Description: Qualtech Products Industry Peel Tester is an Automatic Peel Tester for flexible bonded to rigid test specimen to measure the Adhesive Strength of a wide range of samples at the touch of a button including adhesives. This professional Automatic Peel Tester offers the newest microchip technology combined with a large Color Touchscreen Display, .Typically the goal of a peel test is to determine the adhesive strength of the material or the strength of the adhesive bond between two materials. This adhesive strength may be referred to as the “stickiness” of the material as it is a measure of the resistance of specimens to separate from each other after the adhesive is applied. (a,b) The intra-test CV trends changed to a decreasing trend after peel rate of 0.707 mm/sec for both PTFE and PEEK demonstrating that the asynchronous failures of filaments of adhesive layer is .

Test Procedure: Clamp each ends of the t-peel specimen in separate test grips of the universal tester / tension testing machine. Separate the specimen at a rate of 127 mm (5.0 in) /min for (5-in.) length of the bond line. Specimen size: Specimens are cut from a T-peel panel to 25.4 mm (1.0 in) long x 300 mm (12 in) wide. Ten specimens are .

The store will not work correctly when cookies are disabled. . D1876-08R15E01|en-US Standard Test Method for Peel Resistance of Adhesives (T-Peel Test) Standard D1876 Standard Test Method for Peel Resistance of Adhesives (T-Peel Test)> new BOS Vol. 15.06 Committee D14 $ 73.00 In stock ASTM International. Abstract.

PSTC-3 Peel Adhesion of Double Coated Pressure-Sensitive Tapes at 180° Angle PSTC-4 Adhesion to Liner of Presure-Sensitive Tapes at 180° Angle 3. Terminology 3.1 Definitions—Terminology found in Terminology D 996 shall apply. 4. Summary of Test Method 4.1 Test Method A—Single-Coated Tapes, Peel Adhesion atThe data we provide assists material engineers in the selection of materials in global markets. It includes adhesive strength testing such as tensile, shear, and peel data, as well as other adhesive property tests (e.g., impact, odor, and aging). Testing can be performed in hot/wet/dry conditions at ambient, elevated, or reduced temperatures.

perkin elmer polarimeter calibration

perkin elmer polarimeter cell

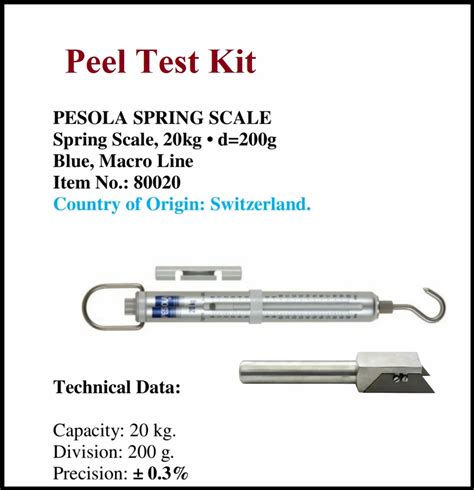

peel testing kit

peel testing equipment

WEBBetway argentina te ofrece la oportunidad de apostar en muchos deportes y mercados diferentes, ya que tiene una larga lista de deportes disponibles. Al ingresar a Betway .

Adhesive Peel Tester store|adhesive peel tester